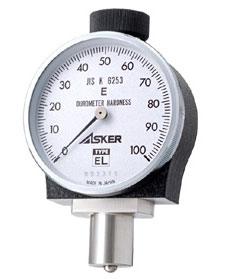

ASKER Durometer Type EL

The ASKER Durometer Type E for soft rubber (low hardness), as specified by JIS K 6253-3 and ISO 48-4.

The application is the same as the standard ASKER Durometer Type C

Widely used for measuring soft rubber, sponges, and other foam elastomers, as well as rolled-threads, -films and textile windings (yarn packages).

Features

Indentor

Height: 2.50mm Shape: Spherical

Hardness Tester Selection Chart

Our product line consists of various types of durometers applicable to specific materials as indicated in the chart above.

Type A Durometer (ASKER A type), conforming to JIS K 6253-3 is the most popular type of durometer for measuring rubber hardness.

However, verification is recommended because a significant difference is estimated to be the largest when a durometer indicates measurement values from 10 to 90 points.

For hard specimens for which Type A Durometer readings indicate more than 90 points, measurements should be undertaken using the Type D Durometer (ASKER D type). However, for soft specimens with measurements of less than 20 points, the ASKER C type or Type E Durometer (ASKER E type) should be used. The most important consideration in using durometers is to select the correct type for purposes of measurement according to the specimen.

Specification

- Standards

-

- JIS K 6253-3

- ISO 48-4

- Indication range

- 0 point - 100 point (262 degree dial scale)

- Minimum indication

- 1 point (Accuracy : ±1 point)

- Indentor Design (mm)

- Height: 2.50 5.00 Dia. Spherical

- Spring Forces [mN(g)]

-

- 0 point:

- 550(56)

- 100 point:

- 8050(821)

- Central hole of diameter of Pressure foot

- Φ5.5

- Pressure foot Dimension (mm)

- Φ16 Longer foot type Length: 18

- Outer Dimension (mm)

- Approx. Width 57×Depth 30×Height 94

- Weight (g)

- 200

- Application

- soft rubber, urethane foam, rubber roller

Outer Dimension (mm)

Option

Two-pointer type (max-hand and active hand) of Rubber Hardness Tester

The stationary set hand (max-hand) makes the maximum value easier to read and allows the creep characteristics of a specimen.

Accurate measurement is made possible for specimens* for which stress relaxation occurs over time or for specimens for which it is difficult to take readings from the front.

*Materials for which the reading decreases immediately after the indentor has been pressed against the surface.

Constant Loader for Durometer

- Constant loarder assures uniform test pressure eliminating false readings due to differences between operators in measuring by hand.

- High accuracy and repeatability of the hardness readings are assured by the flexible joint function.

Indentor Extension Tester

- The gauge to check the indentor height on a durometer and the reading indicator mechanism.

- Inspection is conducted at 2, 50, and 100 points respectively.

Load Tester for Hardness Tester

- Tester to check load properties of the spring on a durometer

- Inspection is conducted at 25, 50, and 75 points respectively.